Weight optimized Lever

Sarholz Engineering • 18. April 2024

Optimization of a Lever

weight reduction of a CNC-machined Lever

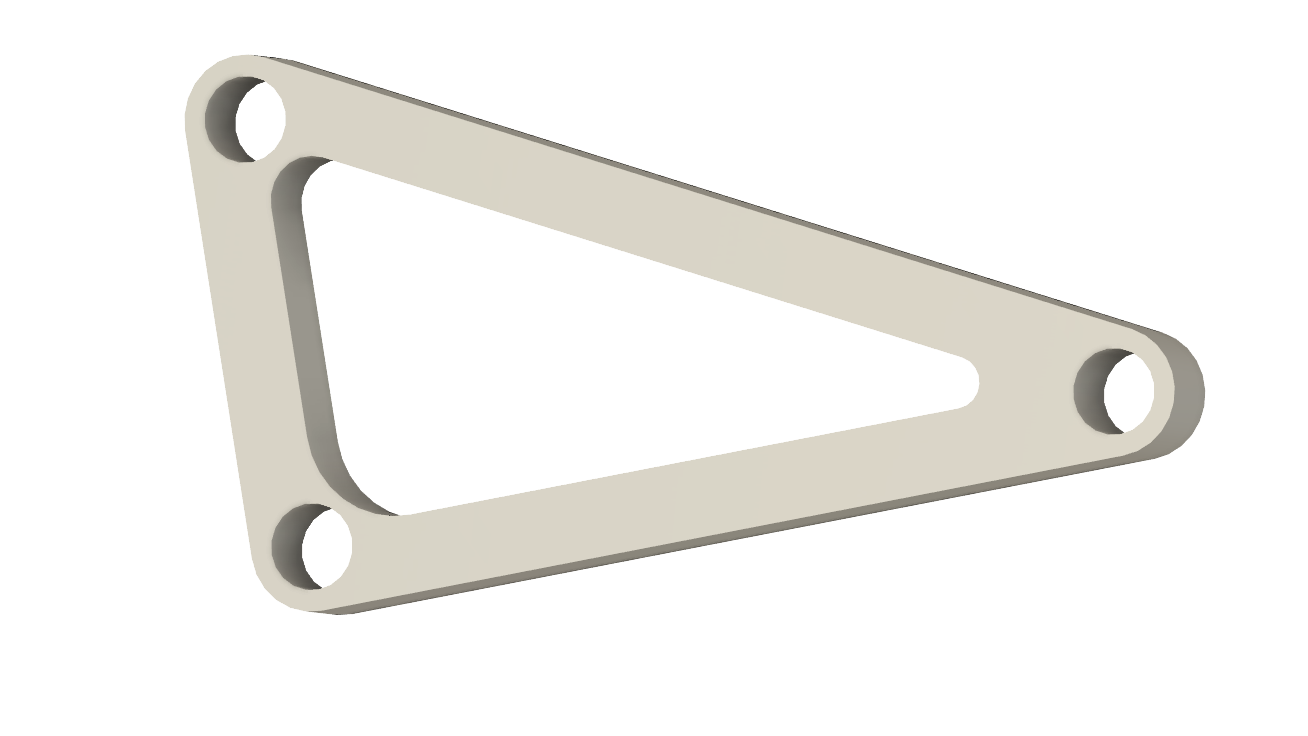

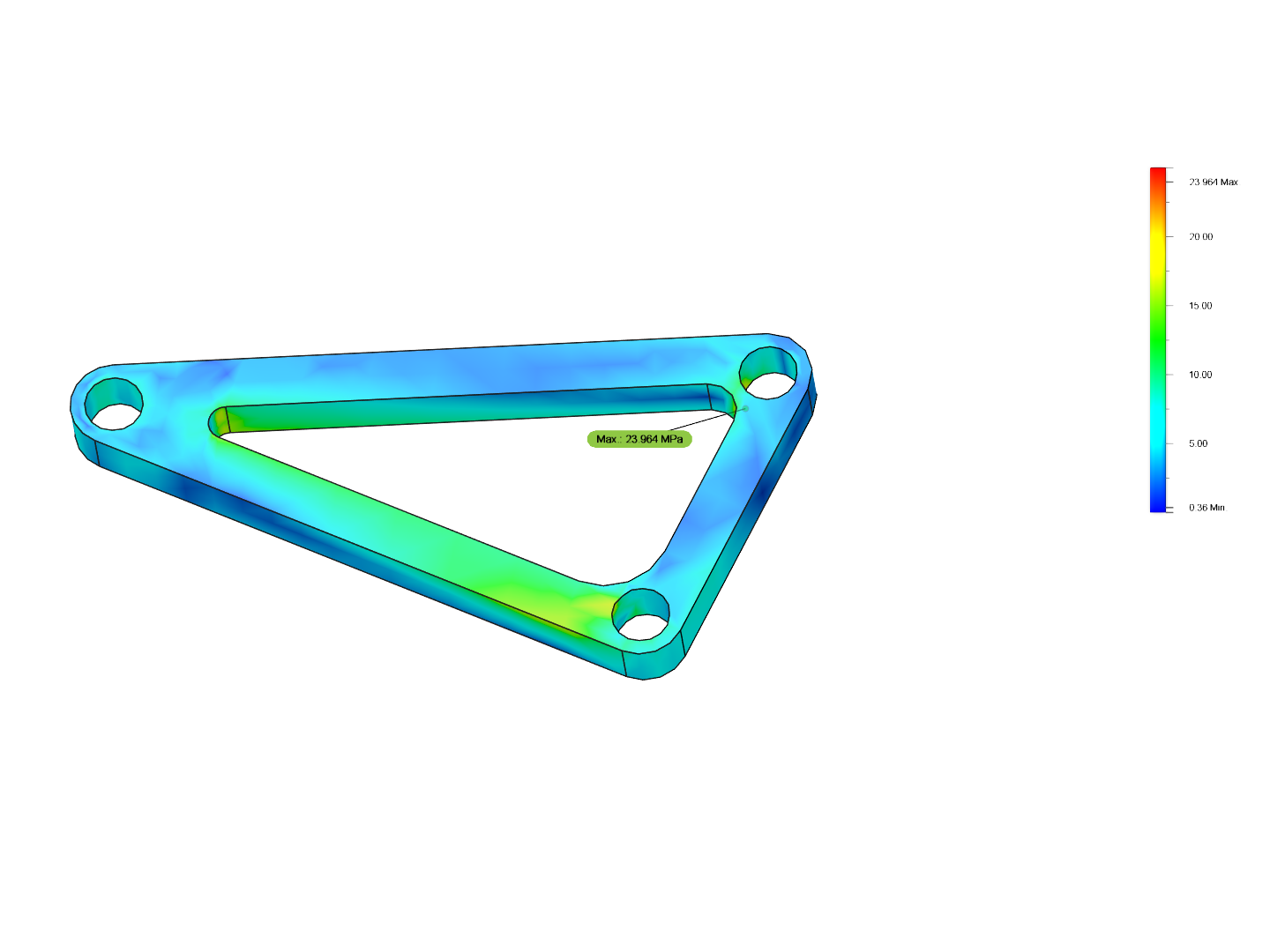

The original part is a simple CNC-machined Lever. It pivots around the bottom bearing. The weight is to be reduced while not changing the Method of production

- Material: EN AW 7075-T6

- Process: milled (2.5 axis)

- Weight: 528 g

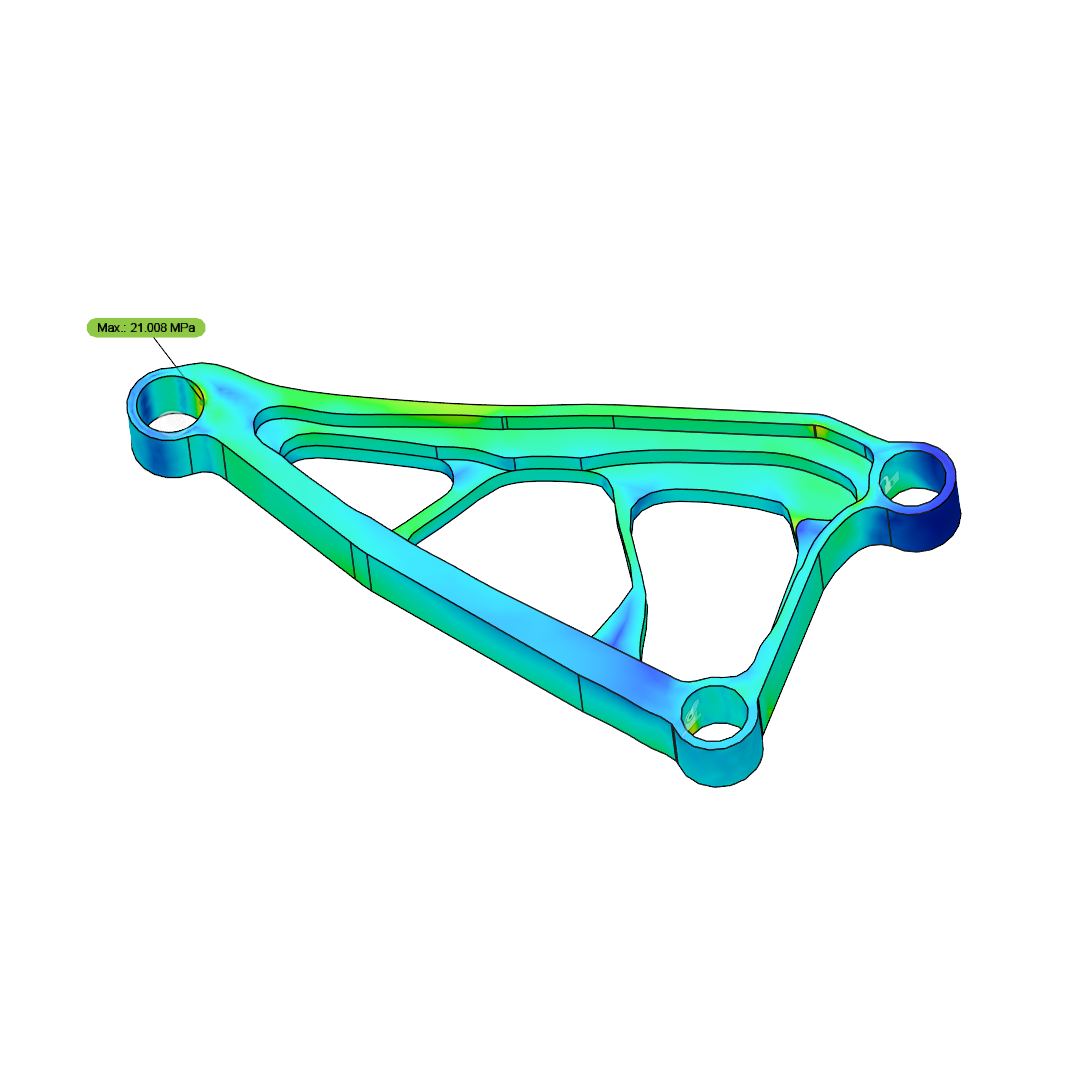

The optimized Design results in a more even stress-distribution. The weight is reduced and the part can be CNC-maschined.

- Material: EN AW 7075-T6

- Process: milled (2.5 axis)

- Weight: 323 g (reduced by 39%)